Inventory Control Techniques That Actually Work

From EOQ to ABC & XYZ: Proven Methods to Optimize Stock and Slash Costs

Inventory control isn’t about how much stock you hold. It’s about how well you manage what matters.

Many supply chain leaders and operations teams struggle with stockouts, bloated warehouses, or locked-up working capital. But the real problem isn’t always demand. It’s ineffective inventory control.

In this guide, I walk you through the most prominent inventory control techniques that top-performing supply chains use—not as theory, but as practical tools tied to business outcomes like:

Lower carrying costs

Improved stock availability

Better forecast accuracy

Reduced waste and working capital

Whether you're a supply chain manager, analyst, or operations leader upskilling in AI and analytics, this is your go-to resource for mastering inventory fundamentals.

📅 Download the Inventory Control Toolkit

Get the complete workbook with templates, formulas, and visuals.

✅ Includes:

ABC/XYZ calculator

EOQ & ROP computation sheets

Inventory segmentation matrix

📢 Share This Post

📆 Subscribe for Weekly Supply Chain Insights

Want more guides like this one? Subscribe to the newsletter for practical playbooks on AI in Supply Chain, inventory optimization, and digital transformation.

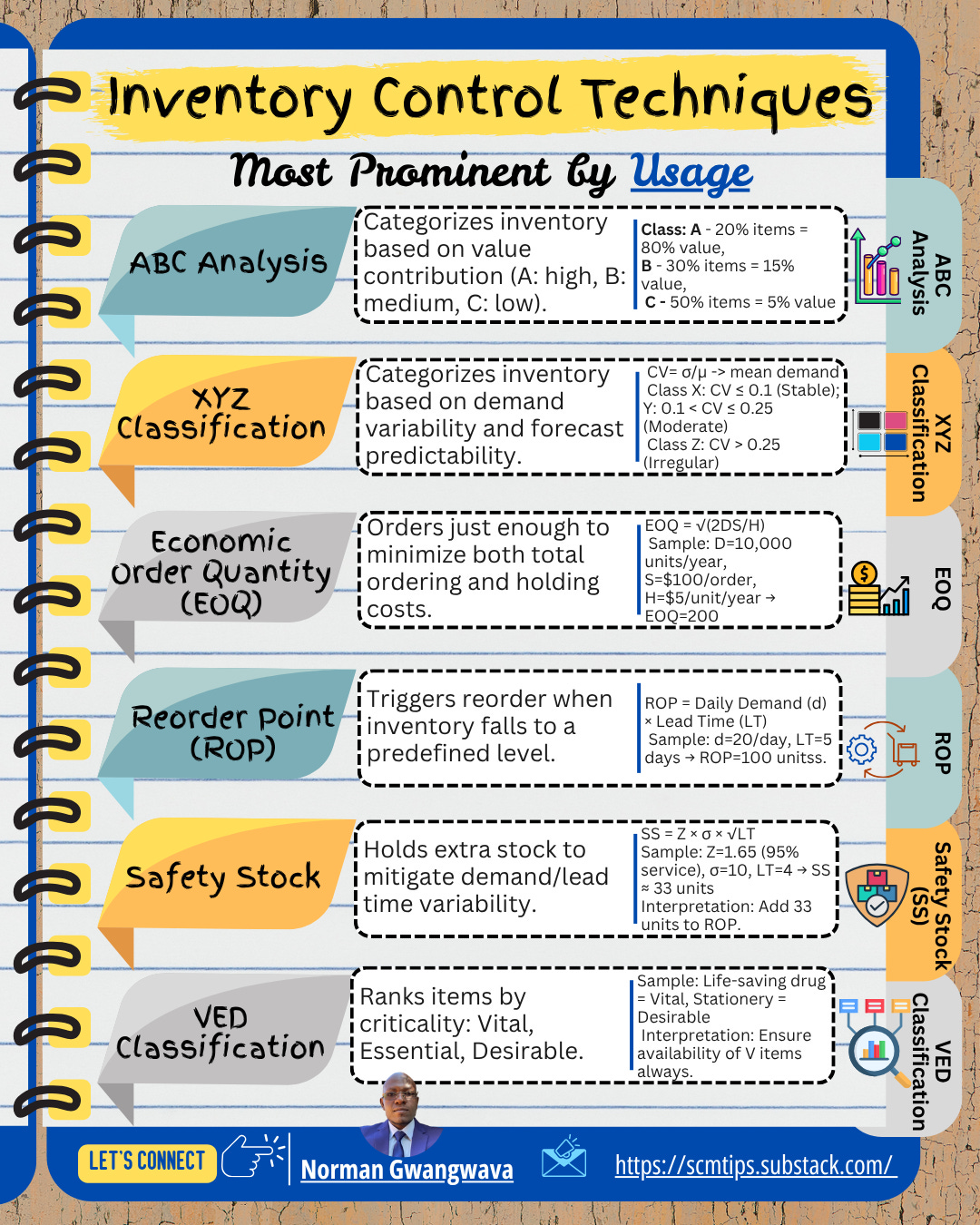

#1 – ABC Analysis

What it is

Categorizes inventory based on value contribution.

A-items = high value, tight control

B-items = moderate value

C-items = low value, basic controls

How it does

Sort SKUs by annual consumption value:

Class A: 20% items = 80% value

Class B: 30% items = 15% value

Class C: 50% items = 5% value

Interpretation: Focus control on Class A, routine check on C.

#2 – XYZ Classification

What it is

Categorizes SKUs based on demand variability.

How it does

Uses Coefficient of Variation:

X: CV ≤ 0.10 (stable)

Y: 0.10 < CV ≤ 0.25 (moderate)

Z: CV > 0.25 (erratic)

Example

SKU2: σ = 12, μ = 120 → CV = 0.10 → Class X

Interpretation

Class X: low safety stock Class Z: high buffers, flexible replenishment

#3 – Economic Order Quantity (EOQ)

What it is

Optimizes how much to order to minimize holding and ordering cost.

How it does

Where:

D = Annual demand

S = Order cost

H = Holding cost per unit

Example

D = 4,800; S = $100; H = $10 → EOQ = 309 units

Interpretation

Order in lots of 309 to balance ordering vs. holding cost.

#4 – Safety Stock

What it is

Extra stock held to absorb demand or lead time variability.

How it does

Z = Z-score for service level

Example

Z = 1.65, σ = 15, LT = 4 → SS = 1.65 × 15 × 2 = 49.5 units

Interpretation

Use to avoid stockouts under variability.

#5 – Reorder Point (ROP)

What it is

The inventory level that triggers a replenishment order.

How it does

Add safety stock if needed:

Example

Demand = 30/day, LT = 5 days, SS = 50 → ROP = 200

Interpretation

Prevents late reordering and stockouts.

#6 – Two Bin Technique

What it is

Visual system using two bins: working + reserve stock.

How it does

Use from Bin 1. When empty, reorder using Bin 2 reserve.

Example

Bin 1 = 100 units, Bin 2 = 50 (covers LT demand)

Interpretation

Ideal for manual environments or maintenance stores.

#7 – VED Classification

What it is

Ranks items by criticality.

Vital

Essential

Desirable

How it does

Subjective based on operational impact.

Example

Ventilator part = Vital; Office supplies = Desirable

Interpretation

Use in healthcare, aerospace, and public sector systems.

#8 – HML Classification

What it is

Ranks items by unit price.

How it does

Sort by per-unit cost:

High, Medium, Low

Example

Sensor = $1,200 = High Bolt = $1 = Low

Interpretation

Focus controls on high-cost SKUs.

#9 – SDE Classification

What it is

Ranks by procurement difficulty:

Scarce

Difficult

Easy

How it does

Assessed by buyer or planner based on market access

Example

Specialty chip = Scarce; Local cap = Easy

Interpretation

Helps adjust lead time buffers and sourcing strategy.

#10 – FSN Classification

What it is

Ranks by consumption velocity:

Fast, Slow, Non-moving

How it does

Measured by transaction frequency over a time period.

Example

SKU sold weekly = Fast SKU unused in 6 months = Non-moving

Interpretation

Use to clean up dead stock and rationalize SKUs.

#11 – Order Cycling System

What it is

Fixed-interval review system.

How it does

Review and reorder stock on scheduled dates.

Example

Every 1st and 15th of the month.

Interpretation

Useful in stable environments, low admin effort.

#12 – Just-In-Time (JIT)

What it is

Minimizes on-hand inventory by syncing supply with demand.

How it does

Requires tight supplier integration and fast lead times.

Example

Auto plant receives wheels 1 hour before assembly.

Interpretation

Reduces waste, but vulnerable to disruption.

📩 Stay Ahead

🤔 Let’s Talk

I’d love to hear your thoughts about inventory control practices.

What’s your go-to method for inventory control?

Do you combine techniques like ABC+XYZ, run MRP-based planning, or DDMRP?

Drop a comment or share your experience.

Your insights might help shape how others approach their AI in Supply Chain journey.